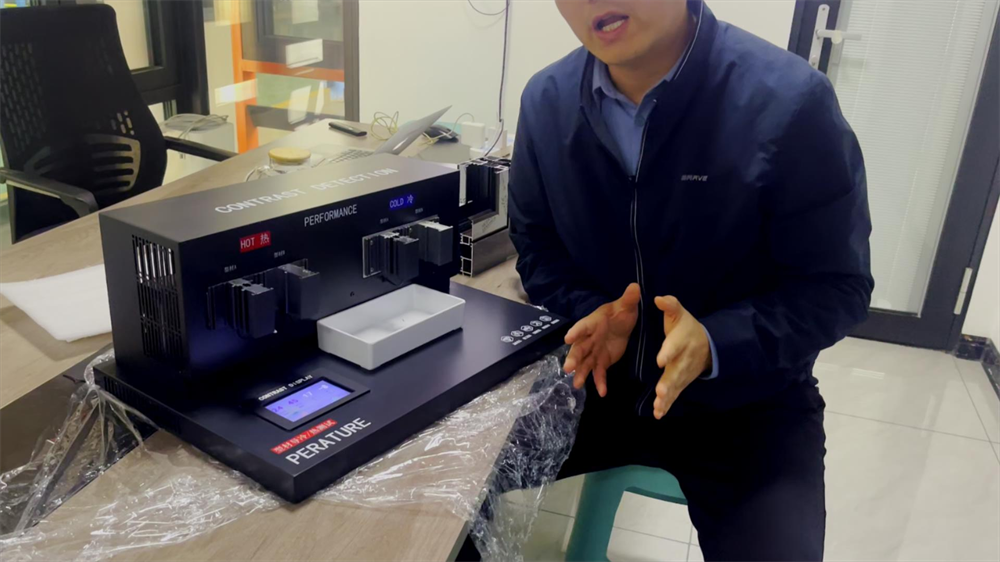

Weifang, March 25, 2025 —— Shandong Meidao System Doors & Windows Co., Ltd. today announced the launch of its cutting-edge MeiDoor Thermal break System Window Thermal Insulation Test Bench. This innovative platform visually demonstrates the dramatic difference in thermal performance between MeiDoor’s thermal break aluminum frames and conventional aluminum frames through controlled temperature experiments, solidifying the product’s proven energy efficiency. The breakthrough also underscores the company’s compliance with global certifications, including CE, NAMI, NFRC, ENERGY STAR, and AS2047.

Test Bench Mechanics and Key Findings

The test bench simulates extreme temperature differentials to monitor real-time heat transfer rates. Data shows that standard aluminum frames, due to their high thermal conductivity, achieve only a 2–3°C temperature gap between inner and outer surfaces. In contrast, MeiDoor’s thermal break frames—featuring a dual-chamber design and thermal barrier strips—maintain a 15–18°C temperature differential. This design significantly reduces U-value (thermal transmittance) by blocking heat exchange between indoor and outdoor environments.

Referencing industry research (e.g., Journal of Building Energy Efficiency Materials), optimized cavity structures with radiant insulation panels (RIPs) can enhance thermal performance. MeiDoor’s test bench validates this theory: its thermal break system windows achieve a 7.43% U-value reduction compared to traditional designs, surpassing the 0.81% improvement of standard aluminum frames.

Global Certifications and Technological Advantages

MeiDoor’s thermal break windows have earned prestigious international accreditations:

• CE Certification (EU safety and energy efficiency standards)

• NFRC & ENERGY STAR (U.S. Department of Energy and EPA certifications)

• AS2047 (Australian window performance standard)

• NAMI (Japanese Building Materials Certification)

Key technological strengths include:

1. Triple-Seal Structure: Premium EPDM rubber strips and seamless welding ensure superior airtightness and watertightness.

2. Insulating Glass Options: Customizable 5+12+5+5mm super-wide hollow layers filled with inert gas minimize heat radiation and noise.

3. Intelligent Cavity Design: Finite element analysis optimizes insulation panel placement for balanced U-value and structural integrity.

Market Impact and Industry Leadership

“Our test bench isn’t just a tool—it’s a redefinition of industry standards,” stated MeiDoor’s CEO. “By democratizing data, consumers can tangibly experience the energy-saving, comfort, and environmental benefits of thermal break aluminum windows.”

As global energy efficiency regulations tighten, thermal break aluminum windows are gaining traction in high-end markets for their balance of aesthetics, durability, and performance. MeiDoor’s test bench not only reinforces its technological edge but also provides a replicable framework for energy efficiency verification across the sector.

Post time: Apr-01-2025