Aluminum alloy system doors and windows are profiles that will be surface treated. Door and window frame components made by blanking, drilling, milling, tapping, window making and other processing techniques, and then combined with connecting parts, sealing parts, and opening and closing hardware.

Aluminum alloy system doors and windows can be divided into sliding doors and windows, casement doors and windows, screen doors and windows, inward opening and inverting windows, shutters, fixed windows, hanging windows, etc. according to their structure and opening and closing methods. According to the different appearance and luster, aluminum alloy system doors and windows can be divided into many colors such as white, gray, brown, wood grain, and other special colors. According to the different production series (according to the width of the section of the door and window profile), aluminum alloy doors and windows can be divided into 38 series, 42 series, 52 series, 54 series, 60 series, 65 series, 70 series, 120 series, etc.

1. Strength

The strength of the doors and windows of the aluminum alloy system is expressed by the level of wind pressure applied during the compressed air pressurization test in the pressure box, and the unit is N/m2. The strength of aluminum alloy doors and windows with ordinary performance can reach 196l-2353 N/m2, and the strength of high-performance aluminum alloy windows can reach 2353-2764 N/m2. The maximum displacement measured at the center of the casement under the above pressure should be less than 1/70 of the height of the inner edge of the window frame.

2. Air tightness

The aluminum alloy window is in the pressure test chamber, so that the front and rear of the window form a pressure difference of 4.9 to 9.4 N/m2, and the ventilation volume per m2 area per h (m3) indicates the airtightness of the window, and the unit is m³/m²·h. When the pressure difference between the front and back of the aluminum alloy window with ordinary performance is 9.4N/m2, the airtightness can reach below 8m³/m²·h, and the aluminum alloy window with high airtightness can reach below 2 m³/m²·h. the

3. Water tightness

The doors and windows of the system are in the pressure test chamber, and the outside of the window is subjected to a sine wave pulse pressure with a period of 2s. At the same time, 4L of artificial rainfall is radiated to the window at a rate of 4L per m2 per minute, and the "wind and rain" experiment is carried out for 10 minutes continuously. There should be no visible water leakage on the indoor side. The watertightness is represented by the uniform pressure of pulsed wind pressure applied during the experiment. The ordinary performance aluminum alloy window is 343N/m2, and the typhoon-resistant high-performance window can reach 490N/m2.

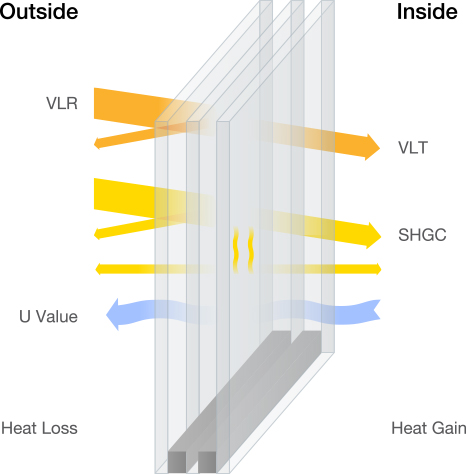

4. Sound insulation

The sound transmission loss of aluminum alloy windows is tested in the acoustic laboratory. It can be found that when the sound frequency reaches a certain value, the sound transmission loss of the aluminum alloy window tends to be constant. Using this method to determine the level curve of sound insulation performance, the sound transmission loss of aluminum alloy windows with sound insulation requirements can reach 25dB, that is, the sound level can be reduced by 25dB after the sound passes through the aluminum alloy window. Aluminum alloy windows with high sound insulation performance, the sound transmission loss level curve is 30~45dB.

5. Thermal insulation

The heat insulation performance is usually expressed by the heat convection resistance value of the window, and the unit is m2•h•C/KJ. There are three levels of ordinary dividends: R1=0.05, R2=0.06, R3=0.07. Using 6mm double-glazed high-performance thermal insulation windows, the thermal convection resistance value can reach 0.05m2•h•C/KJ.

6. Durability of Nylon Guide Wheels

Sliding windows and movable casement motors are used for continuous reciprocating walking experiments through eccentric linkage mechanisms. The nylon wheel diameter is 12-16mm, the test is 10,000 times; the nylon wheel diameter is 20-24mm, the test is 50,000 times; the nylon wheel diameter is 30-60mm.

7. Opening and closing force

When the glass is installed, the external force required to open or close the casement should be below 49N.

8. Open and close durability

The opening and closing lock is driven by a motor on the test bench, and the continuous opening and closing test is carried out at a speed of 10 to 30 times per min. When it reaches 30,000 times, there should be no abnormal damage.

Post time: Jul-24-2023